电缆桥架的表面防腐层类别有哪些呢?实际上主要有热浸锌、镀锌镍、冷镀锌、粉末静电喷涂等方式。

济南电缆桥架生产厂家资料显示:

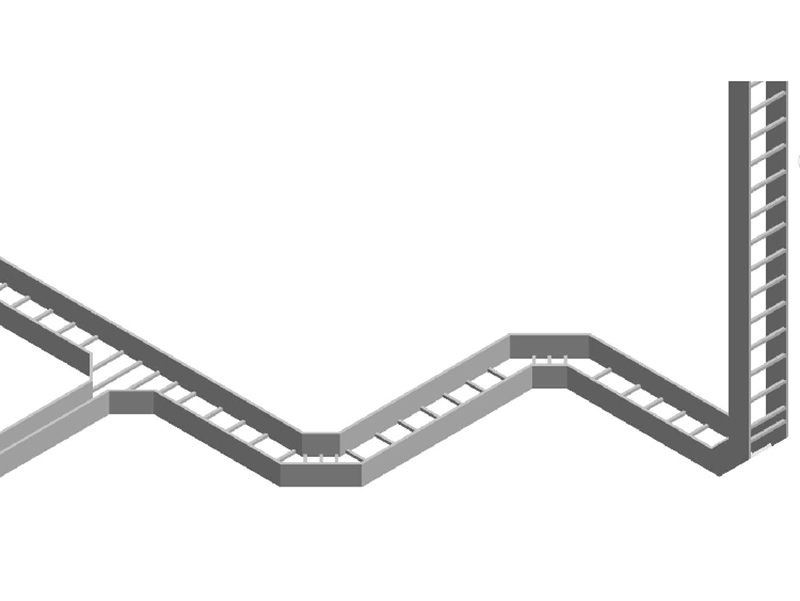

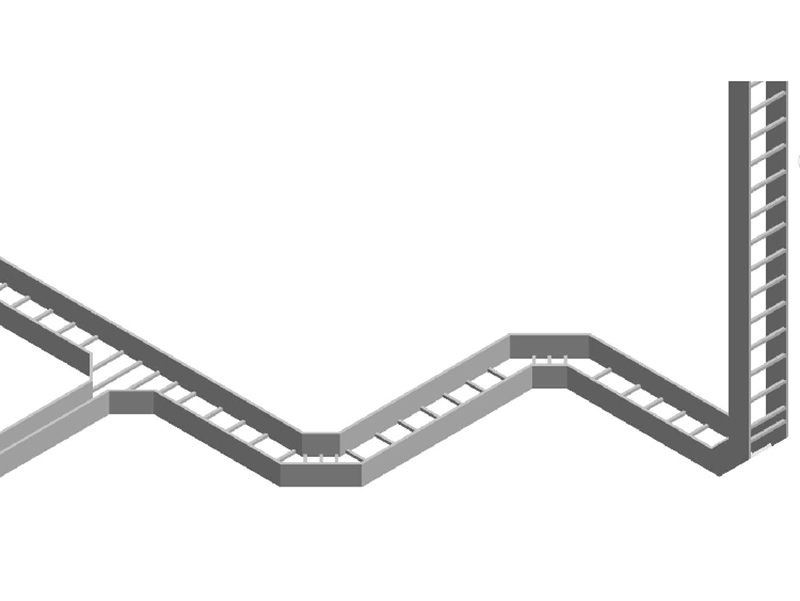

What are the types of anti-corrosion coating on the surface of cable tray? In fact, there are mainly hot dip galvanizing, zinc nickel plating, cold galvanizing, powder electrostatic spraying and other methods. According to the data of cable bridge manufacturers in Jinan:

数据表明,热浸镀锌的工艺寿命不少于40年,适用于室外重度腐蚀环境,成本高;镀锌镍的工艺寿命不少于30年,也适合于室外重度腐蚀环境,成本高;冷镀锌工艺寿命不少于12年,适用于户外轻腐蚀的环境,成本是普通的;粉末静电喷涂工艺的使用寿命不少于12年,适用于室内室温干燥的环境,一般。

The data shows that the service life of hot-dip galvanizing process is not less than 40 years, and it is suitable for outdoor severely corrosive environment with high cost; The service life of zinc nickel plating process shall not be less than 30 years, and it is also suitable for outdoor severe corrosion environment with high cost; The service life of cold galvanizing process shall not be less than 12 years, which is suitable for outdoor light corrosion environment, and the cost is ordinary; The service life of powder electrostatic spraying process shall not be less than 12 years, and it is suitable for indoor room temperature and dry environment, with average price.

对钢表面进行化学清洁,然后将其放入含有氧化锌的电镀液中。直流电在一处连接到钢,锌板在一处连接到电镀液中。通电后,锌以分子状态被置换到钢表面。如果加入增白剂进行钝化,它将反射出彩色的云状明亮涂层。

The steel surface is chemically cleaned and then placed in an electroplating solution containing zinc oxide. Direct current is connected to steel and zinc plate is connected to electroplating solution at one place. After electrification, zinc is replaced on the steel surface in a molecular state. If a whitening agent is added for passivation, it will reflect a colorful cloud like bright coating.

应用于钢结构的镀锌锌通常没有良好的防锈效果,主要是因为未达到镀锌量,并且镀锌不均匀。通常,生锈发生在两到三年内,并且质量差的产品会暴露在潮湿的环境中,并且会在十天内生锈。热浸镀锌层较厚且具有较强的耐腐蚀性。冷浸镀锌层比热浸镀锌层亮,但更薄且抗腐蚀性较弱。

Galvanized zinc applied to steel structures usually has no good rust prevention effect, mainly because the amount of galvanizing is not reached and the galvanizing is uneven. Generally, rust occurs within two to three years, and products of poor quality will be exposed to humid environment and rust within ten days. The hot-dip galvanized layer is thick and has strong corrosion resistance. Cold dip galvanized coating is brighter than hot dip galvanized coating, but thinner and less corrosion resistant.

工程设计中的三个普遍问题是热浸锌电缆桥架的类型没有标记防腐蚀层的类型,并且没有统一的文字描述。这个问题实际上是一个教训。

Three common problems in engineering design are that the type of hot-dip galvanized cable tray is not marked with the type of anti-corrosion coating, and there is no unified text description. This question is actually a lesson.

设计人员应该根据工程环境条件合理选择电缆桥架的表面防腐层类别,并在设计文件中清晰地表达。电缆桥架在有防火要求的区段内,可在电缆梯架、托盘内添加具有耐火或难燃性能的板、网等材料构成封闭或半封闭式结构,并采取在桥架及其支吊架表面涂刷防火涂层等措施,其整体耐火性能应满足有关规范或标准的要求。

The designer shall reasonably select the type of anti-corrosion coating on the surface of cable tray according to the environmental conditions of the project, and clearly express it in the design documents. In the section with fire protection requirements for cable bridge, plates, nets and other materials with fire resistance or flame retardant properties can be added in cable ladder and tray to form a closed or semi closed structure, and measures such as painting fire retardant coating on the surface of cable bridge and its supports and hangers shall be taken. The overall fire resistance shall meet the requirements of relevant national codes or standards.

This is all about the category of anti-corrosion coating on the surface of cable tray. If you have any questions, you can come to us at any time http://www.sddlqj.cn Understand!

山东电缆桥架的承载能力怎么计算?

山东电缆桥架的承载能力怎么计算?